Quality Control Process

- By : BokTech team

Quality control is a process for maintaining proper standards in manufacturing. Customers should be clear to recognize that quality is an important attribute in products and services. BokTech recognizes that quality can be an important differentiator between their own offerings and those of competitors.

So BokTech keeps raising our own standards of quality in order to meet International standards and customer demands.

Quality is the life of an enterprise, to avoid defective product come to customer, BokTeck have strict quality control process.

1. Procurement: We will purchase all the materials from our reliable supplier locally or internationally, like Mouser/Digikey. We have our quality standard and require our suppliers to meet the quality control.

2. IQC (Incoming Quality Control): Incoming quality control is the process to inspect the raw and component materials from suppliers upon arrival. Before all materials come to BokTeck’s warehouse, we will do strict IQC to ensure the materials quality.

3. IPQC (In-process Quality Control): IPQC refers to the quality control during the assembly process. It is very important because you can detect and handle the problem that accurs ahead of time.

4. FAI (First Article Inspection): To avoid volume quality problem, we make a FAI to do function testing and confirmed, especially for mass production.

5. Visual check: To confirm the components’ package, which need to match with PCB design.

6. Function testing: We will do the function testing (based on customer’s test plan) of PCBA to make sure each board works perfect, especially for mass production.

7. FQC (Final Quality Control): To control the finished product in terms of quality for the final result of the work done.

8. OQC (Outgoing Quality Control): OQC is the inspection of products before shipping. It's a crucial step in ensuring the shipment is defect-free.

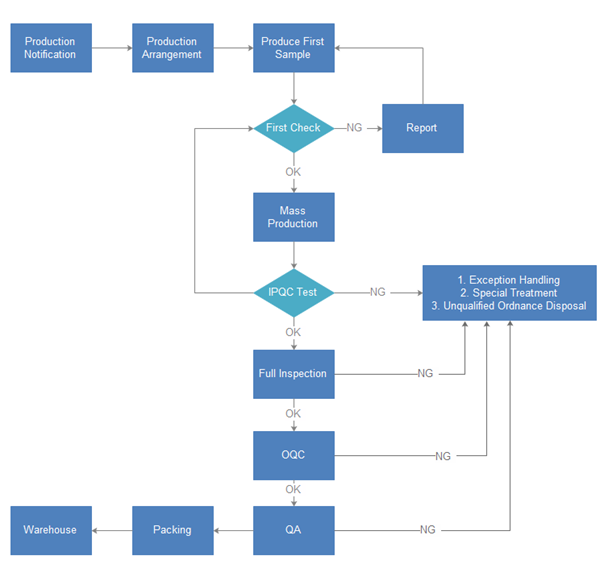

The following is our flowchart of the IPQC process.

- Prev : SMT Stencil

- Next : Packaging